Stepping into the world of 3D printing feels like unlocking a secret workshop where designs born in code become tangible objects. Whether you’re crafting intricate miniatures, custom replacement parts, or functional prototypes, your desktop printer is only as capable as the tools and materials you feed it. Enthusiasm alone won’t banish under-extrusion lines or warped corners. To reach consistently successful prints, you must assemble a toolbox of supportive accessories: measuring devices, reliable filaments, proper build surfaces, and maintenance kits. Each of these components collaborates behind the scenes to ensure your creative vision emerges intact.

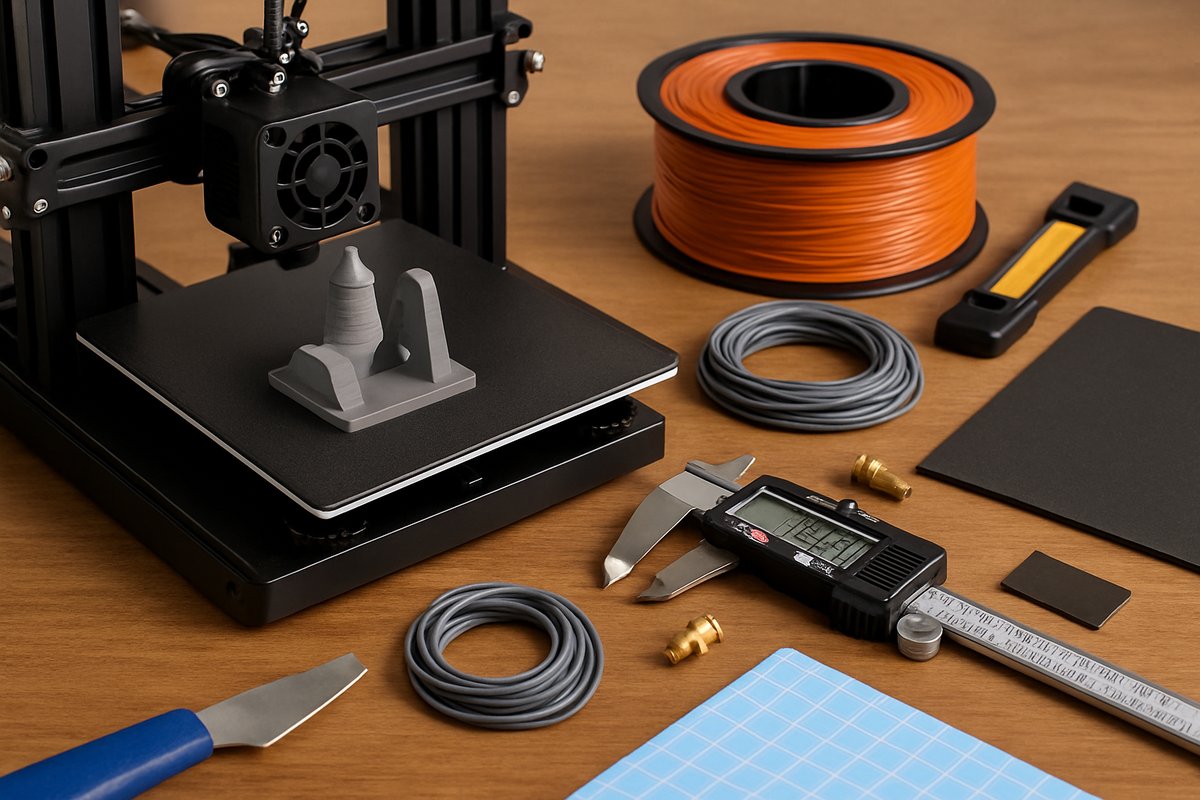

The foundation of any precise 3D printing setup begins with calibration. Even a factory-aligned printer can drift out of spec over time. A slight offset in steps per millimeter or an uneven bed can turn a sleek vase into a wobbly tower. To combat this, you need instruments that offer real-world feedback. A digital caliper is invaluable for measuring the width of test cubes, the thickness of printed layers, and the diameter of nozzles. By comparing measured dimensions to expected values, you’ll dial in extrusion multipliers, adjust belt tensions, and fine-tune belt eccentricity knobs long before frustration sets in. Accurate readings pave the way for perfectly interlocking gears, snap-fit joints, and mechanical clearances you can trust.

But calibration is only half the battle. Once your axes move true, you’ll need to feed them with consistent, high-quality filament. With dozens of polymers on the market-including PLA, ABS, PETG, TPU and specialty blends-variations in diameter, moisture content, and chemical composition can wreak havoc on your prints. A damp polyester filament snarls in the hot end, leaving steam bubbles and brittle layers. An inconsistent diameter triggers over- or under-extrusion, creating weak spots or blobs. That’s why choosing a trusted filament source and storing spools in airtight containers with desiccants is critical. Stock up on a selection of colors and materials to experiment with rigidity, flexibility, and impact resistance without scrambling mid-project.

As your filament feeds smoothly, your first layer becomes the new battleground. A warped or detached print can mean hours wasted. Traditional masking tapes, adhesives, or hairspray offer stopgap fixes, but they wear out and leave residue. Investing in a high-quality build surface kit-such as a flexible spring steel sheet coated with a polymer film-solves adhesion dilemmas. These sheets stick firmly to the print bed with magnets or clips and provide consistent grip across the entire platform. When your object cools, simply peel back the sheet and watch prints pop free without spatulas or chipping the glass. A reliable build surface translates to predictable prints and a less cluttered, more inspiring workspace.

Even the best suppliers age with use. Nozzles clog, rods collect grime, and belts stretch. A compact maintenance toolkit featuring nozzle-cleaning needles, replacement PTFE tubing, lubricant for linear rails, and spare nozzle tips can save you more than frustration-it can save you hours of downtime. Regularly inspecting and cleaning parts before they fail keeps print quality sharp and maximizes uptime. When you assemble this kit, include a small set of hex keys, open-wrench spanners, and extra zip ties. The goal is to handle any minor jam or loose stepper motor pulley in minutes rather than losing an entire weekend troubleshooting.

Once your machine hums along reliably, attention turns to post-processing. Support removal, surface smoothing, and color detailing are the final touches that elevate a print from functional to gallery worthy. Invest in a small set of needle files, sandpapers of various grits, and a handheld rotary tool with sanding and polishing bits. These accessories refine edges, soften layer lines, and allow you to sculpt small features with precision. For extra finesse, a simple primer spray and acrylic paints can transform raw PLA or PETG into lifelike miniatures, colored prototypes, or decorative objects that look as if they were milled from solid metal.

Safety should never be an afterthought. Small fires can start if filaments overheat, and volatile vapors from high-temperature materials demand proper ventilation. A compact smoke detector near your printer and an enclosed ventilation hood or filter can mitigate risk. Pair this with printed safety goggles and heat-resistant gloves for handling hot beds and freshly extruded parts. A clutter-free environment and proper protective equipment ensure your creative flow isn’t interrupted by avoidable hazards.

For those who share prints online or sell small batches of custom parts, backup drives and cloud storage count as must-have accessories. Your slicing profiles, customized printer settings, and original CAD files represent months of fine-tuning and experimentation. Automated backups to a secure server keep these digital assets safe. Later, if you upgrade to a new printer model, you can transfer your perfected configurations without starting from scratch.

Lastly, don’t underestimate the power of ergonomics and organization. A rotating storage carousel for filament spools, a well-lit workspace with adjustable task lighting, and third-angle measurement templates keep the process smooth. A sturdy, vibration-dampening stand can reduce noise and print defects caused by external tremors. Arranging your workstation so that tools are within arm’s reach, cables are neatly routed, and waste materials are contained will help you stay immersed in the craft without friction.

Investing in these accessories may feel like an extra expense on top of an already budget-friendly hobby, but each item compounds into saved time, fewer failed prints, and more polished results. Whether you’re just starting or you’ve printed hundreds of parts, adopting these tools can accelerate your learning curve, sharpen your print quality, and inject renewed confidence into every layer you lay down. From the first test cube to the final prototype, the right combination of calibration, material handling, build surfaces, maintenance supplies, and finishing tools will empower you to push the boundaries of your imagination.

Whether your next project involves rapid prototyping, custom cosplay pieces, or functional engineering parts, these accessories form the invisible scaffolding that supports your entire 3D printing workflow. They transform common roadblocks into stepping stones, replacing guesswork with data, adhesion struggles with easy release, and maintenance chaos with a methodical routine. Building this toolkit is not an indulgence; it’s the solid foundation every serious maker needs to ensure that creative sparks don’t fizzle out at the first sign of error codes or bed leveling frustrations.

In a field where precision matters at the fraction-of-a-millimeter level, neglecting the details of measurement, material storage, bed adhesion, and maintenance invites costly mistakes. Equip yourself with a calibrated digital caliper, a selection of dimensionally accurate filament spools, and a modern removable build surface. Keep a well-stocked maintenance kit close at hand, refine your prints with a focused finishing set, and safeguard your workspace with basic safety gear and backups. These carefully chosen accessories may seem peripheral, but they’re the unsung heroes of repeatable success. When every layer aligns and each part pops off the bed in perfect shape, you’ll understand how much the right tools can elevate every print from a hopeful endeavor into a reliable creative process.

No affiliate links found for this post.